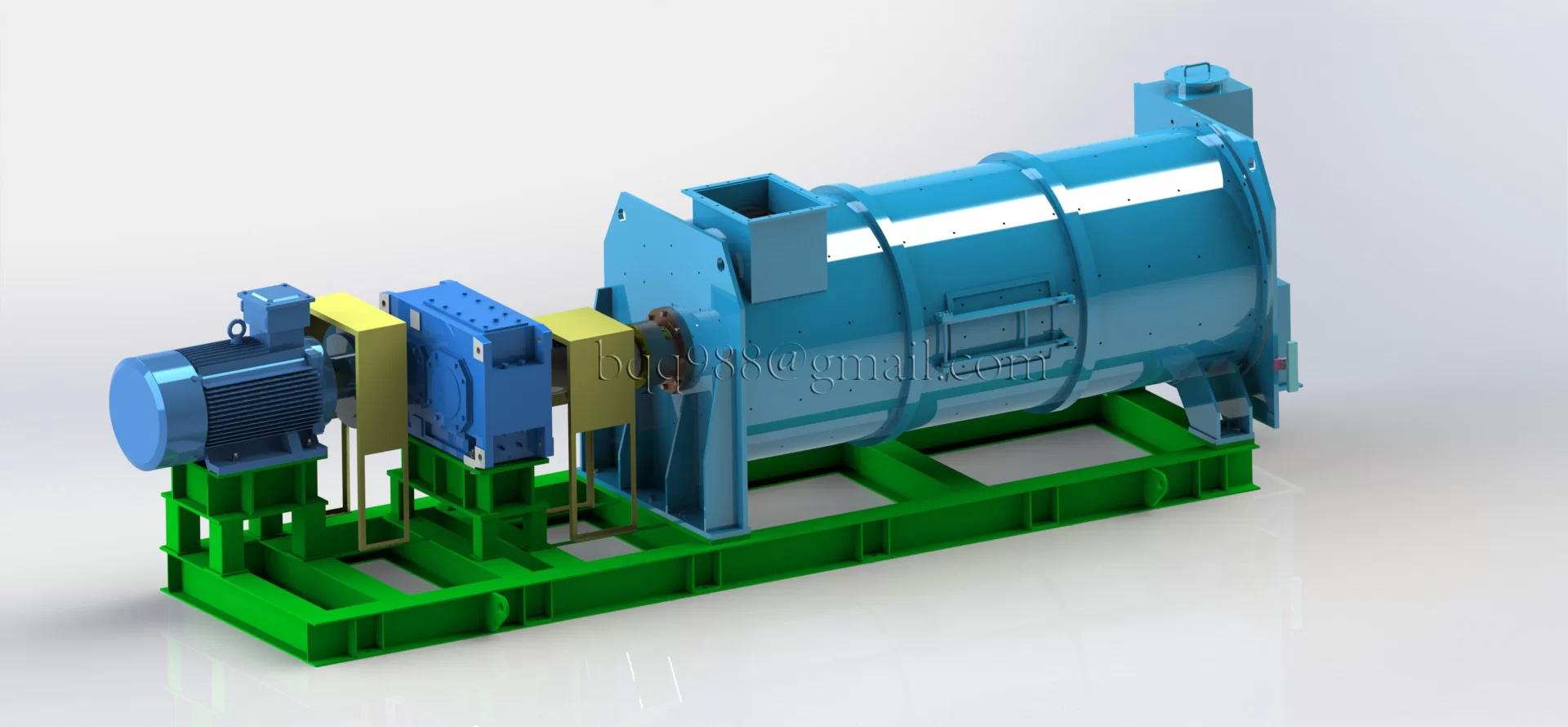

The Horizontal Intensive Mixer

What

As a branch of mixers, the Horizontal Intensive Mixer employs multiple mixing mechanisms such as shear, convection, and diffusion. It can complete material blending in an extremely short time, thus offering advantages like high efficiency and large capacity. This mixer is widely used in the recycling and reuse of metallurgical dust and sludge, as well as in iron ore pelletizing (e.g., lateritic nickel ore, iron concentrate powder, magnesium oxide powder, bauxite powder). It is primarily utilized in industries such as metallurgy, mining, refractory materials, coal, chemical engineering, and building materials.

Key Components

Under normal circumstances, the Horizontal Intensive Mixer is driven by a motor connected via a coupling (or fluid coupling) to a standard reducer. This reducer then transmits power through a gear coupling to drive the rotor assembly. The mixing tools, mounted on the rotor assembly, are the core components. Through their specific geometric design, they rapidly propel the materials to complete the mixing process.

Features

The Horizontal Intensive Mixer primarily features the following characteristics:

1:The mixing tools' surfaces are usually treated with special processes to significantly extend their service life.

2:The mixing tools feature a specially designed layout, which can greatly enhance the final mixing effectiveness.

3:The liner is made of rubber-based polymer material, which effectively prevents material sticking.