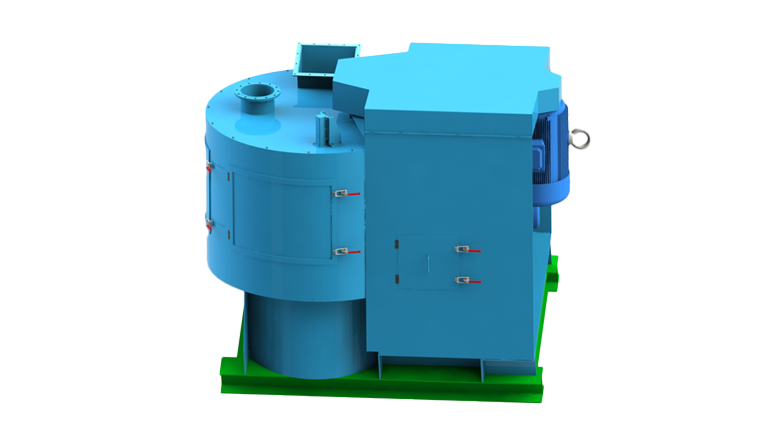

Vertical Intensive Mixer

What

The Vertical Intensive Mixer achieves its mixing action through the coordinated movement of a rotating drum, rotors, and scraper blades. Each full rotation of the drum ensures thorough mixing of the material batch. The specially designed rotors and scraper blades effectively prevent segregation issues common in other mixer types, while simultaneously delivering superior final blend uniformity. This makes it a highly advantageous mixing solution with exceptional performance characteristics.

Key Components

Key Components of the Equipment:

Scraper Blades:

Actively aid in the mixing process by dispersing materials and facilitating discharge.

High-Energy Rotor:

The core mixing component. Driven by a motor via a belt-driven pulley system, it operates at high rotational speeds.

Outer Drum:

Rotated by a motor and gear reducer unit. This motion imparts movement to the materials inside.

Machine Frame:

Provides the structural base, housing and integrating all components into a unified system.

Features

1:High Mixing Efficiency: Delivers approximately 30% greater mixing capacity than conventional mixers, achieving thorough blend homogeneity in significantly reduced cycle times.

2:Minimized Wear Parts: Features a simplified internal design with fewer components contacting the material, ensuring long-term operational stability and reduced maintenance costs.

3:Exceptional Material Versatility: Effectively handles blends containing trace minor additives alongside bulk ingredients without compromising mixing uniformity.

4:Automation-Ready Operation: Engineered for seamless integration with automated control systems (e.g., PLCs, load cells), enabling smart production line upgrades.

5:Streamlined Maintenance: Incorporates quick-access design features that maintain robust component integrity while drastically reducing downtime for part replacement.