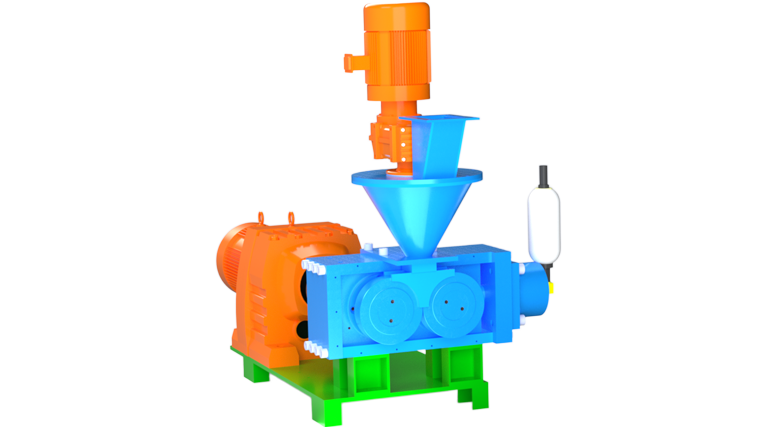

Small briquette machine

why

Briquetting machine handle all sorts of materials, right? But here's the thing - every client's feedstock acts differently. Some stick like glue, some have small granules, others can't decide how wet they want to be. That's why we keep saying: Test before you invest! Get to know your material's quirks, then we'll set you up with the right gear. Trust me, this makes or breaks your production flow later.

Difficult points

Developing this experimental samll briquette machine is absolutely critical! It must tackle two key missions: First, precisely map the material's "personality fingerprint" – think of it as giving raw materials a complete diagnostic workup. Second, despite being a compact lab-scale unit, its roller linear pressure must match those hulking full-scale production machines. Juggling both precision testing and industrial-grade compaction specs? That's where the real technical tightrope walk happens.

Finally

After years of tinkering and tweaking, we've finally nailed this Small briquetting machine! Here's the kicker: it works magic with just a few kilos of material each time, spits out results in minutes, and guess what? The whole setup is so compact it fits on your lab bench