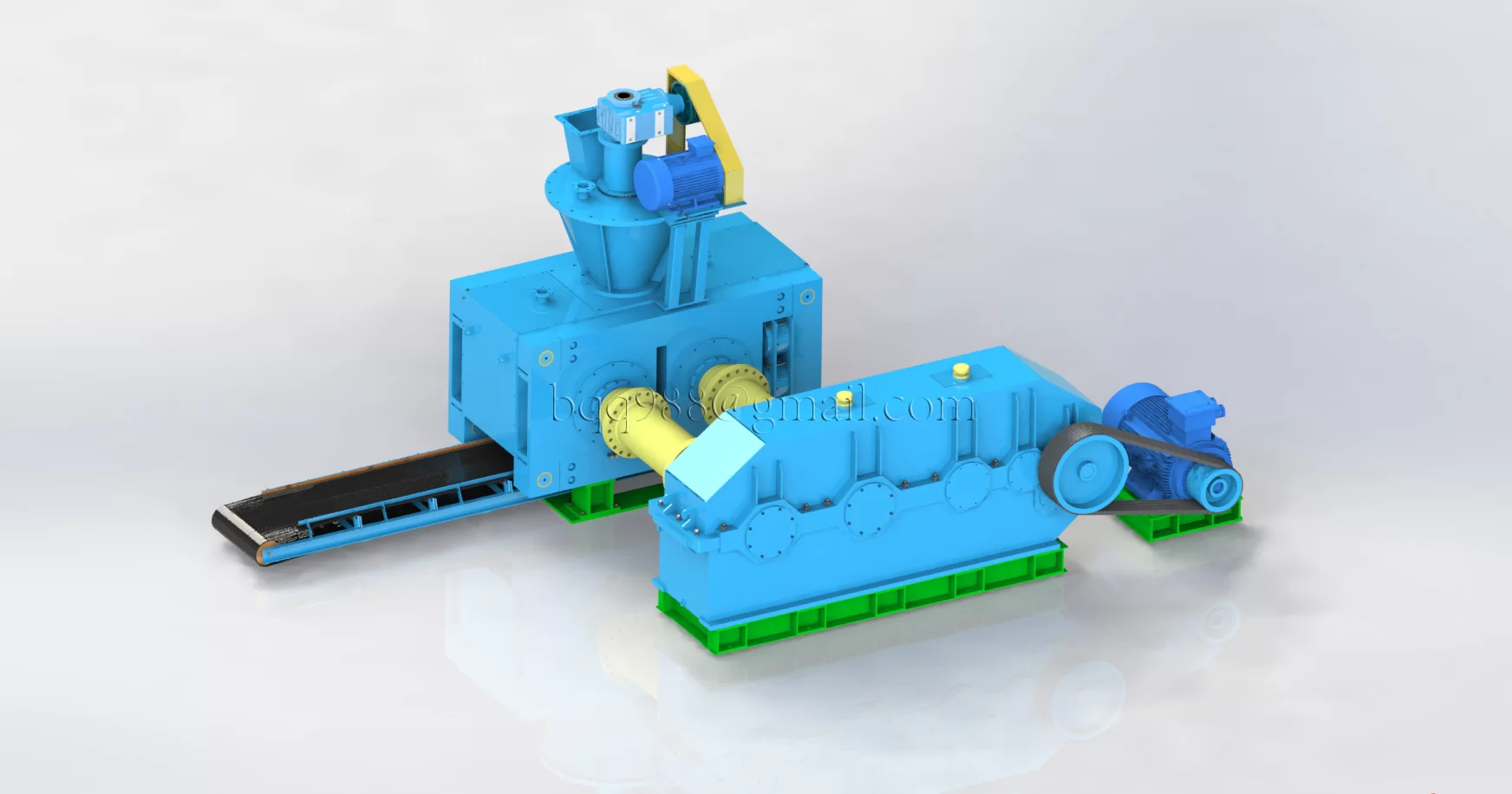

What is a briquette machine

1:Main structure

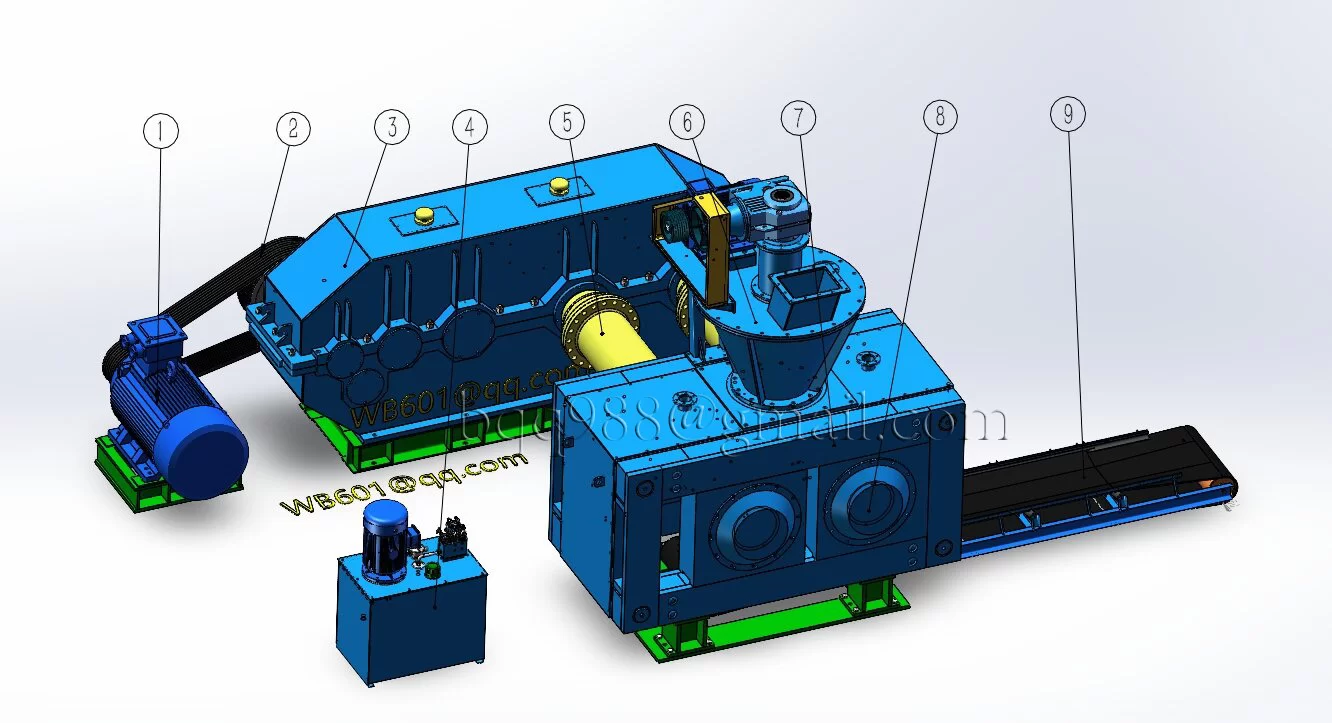

The high-pressure briquetting machine(briquette machine) is primarily composed of the following components (as shown in the diagram below):

1: Motor 2: Belt Drive 3: Gearbox 4: Hydraulic Station 5: Spline Shaft Gear Coupling

6: Pre-Compression Screw 7: Frame Assembly 8: Roller Assembly 9: Discharge Belt

6: Pre-Compression Screw 7: Frame Assembly 8: Roller Assembly 9: Discharge Belt

2:Key features

1. Transmission System

The transmission system operates as follows: Motor → Belt Drive → Double-Shaft Hardened Gear Reducer → Gear Coupling → Roller. Key advantages include:

●Pure Torque Output: Ensures efficient power transfer without lateral forces.

●Large Roller Displacement: Enhances production stability and extends roller lifespan.

●Hydraulic Pressure Adjustment: Enables flexible briquetting force control for adaptability to diverse material conditions.

2. Gearbox

●Custom Double-Output Shaft Gearbox: Hardened gears optimized for heavy-duty, low-speed operations.

●Design Specifications:

Theoretical lifespan: 5 years under extreme load conditions; actual service life exceeds this with proper maintenance.

●Lubrication System:Gears: Oil lubrication.

Bearings: Splash lubrication (standard) or forced internal circulation lubrication (for large machines).

Optional oil coolers/heaters for environmental adaptability.

3. Gear Coupling

●Two Sets Installed: Allow radial displacement of the movable roller (2–15 mm) while maintaining torque transmission.

●Design Features:Each coupling handles 3/5 of total torque.

●Medium-hardened gear surfaces (HB240–270).

●Groove Alignment Mechanism: Ensures precise circumferential alignment of roller molds.

4. Frame Assembly

●Structure: Composed of 8 beams (2 upper, 2 lower, 4 vertical) connected via hinged pins for easy disassembly.

●Adjustment Mechanism: Axial alignment system for roller grooves.

5. Roller Assembly

●Dual Roller Configuration: One fixed, one radially movable via hydraulic cylinders integrated with vertical beams.

Material & Construction:

●High-Quality Bearing Steel: Surface hardness ≥ HRC58 post-heat treatment (high strength, wear resistance).

Shaft Design:

●Fixed at one end, movable at the other.

●Withdrawal Sleeve Bearings: Simplify assembly and maintenance.

●Sealing: Labyrinth seals + rotating lip seals for contamination protection.

●Roller Structure: Integral hot-assembly design with replaceable sleeves to prevent shaft damage.

6. Pre-Compression Screw

●Core Function: Critical for compacting challenging materials into uniform briquettes.

●Design Innovations:

Variable-Pitch Screw: Precision-engineered for optimal compression (refined through decades of practical expertise).

Variable Frequency Drive (VFD): Adjustable speed via dedicated reducer.

7. Hydraulic System

●Function: Powers the movable roller via 4 synchronized hydraulic cylinders.

●Components:

Motor, plunger pump, coupling, oil tank, valve blocks, pipelines.

Relief valve, check valve, accumulator, pressure gauge, sensors.

●Max Pressure: 31.5 MPa.