The meaning of briquetting

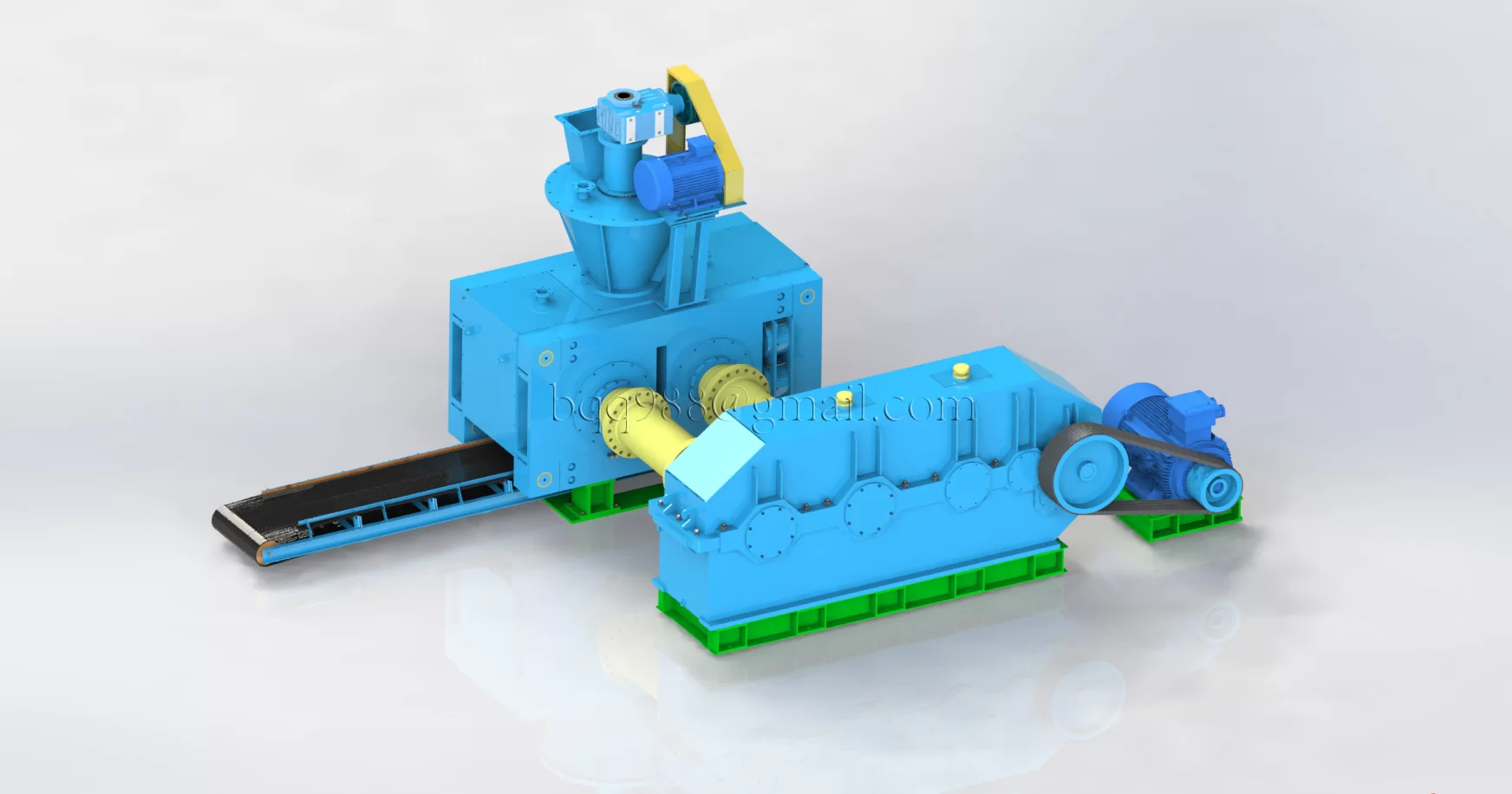

The high-pressure briquetting press(briqutte machine) is an industrial compaction system designed to transform powdered or granular feedstocks into precisely shaped spherical agglomerates under extreme compression. This advanced equipment finds extensive applications across metallurgical processing, chemical manufacturing, coal beneficiation, environmental remediation, and construction material production sectors. Engineered for industrial efficiency, the resultant briquettes demonstrate superior structural integrity with density-optimized pellet formation, while offering configurable geometry specifications to accommodate diverse application requirements. The system's operational excellence is further enhanced by its automated production workflow and industrial-scale throughput capacity, making it particularly suitable for high-volume manufacturing environments.

The compaction process transforms loose powdered substances into high-density spherical briquettes or compacted blocks, significantly enhancing material structural integrity while optimizing industrial-scale logistics through improved transportability, storage efficiency, and downstream processing readiness. The high-pressure compression mechanism effectively eliminates interstitial voids within the material matrix, achieving bulk density enhancement that directly reduces per-unit freight costs and warehousing space requirements by 30-45% compared to loose material handling.

The advanced reclamation of industrial waste streams (including metallurgical dusts, slag byproducts, and mining tailings) through briquetting compaction enables value-added raw material recovery while significantly diverting industrial byproducts from landfill deposition, achieving closed-loop production systems with 60-75% waste volume reduction rates.

The material reactivity enhancement mechanism is achieved through engineered densification processes. In smelting applications, the structural integrity of briquettes facilitates improved permeability of combustion-enhancing gases within furnace chambers, enabling superior thermal uniformity and accelerated reaction kinetics compared to raw powder feedstocks.

he integrated particulate dispersion control system achieves 90% airborne dust suppression efficiency, aligning with ISO 14000 industrial emission protocols. This engineered solution concurrently reduces workplace particulate matter concentrations below OSHA PEL thresholds, effectively mitigating cross-process contamination risks while enhancing occupational safety compliance metrics.

The cold compaction process eliminates the requirement for high-temperature sintering protocols, enabling 30-50% energy consumption reduction and 20-35% operational cost savings within energy-efficient manufacturing frameworks, particularly advantageous for heat-sensitive material processing applications.