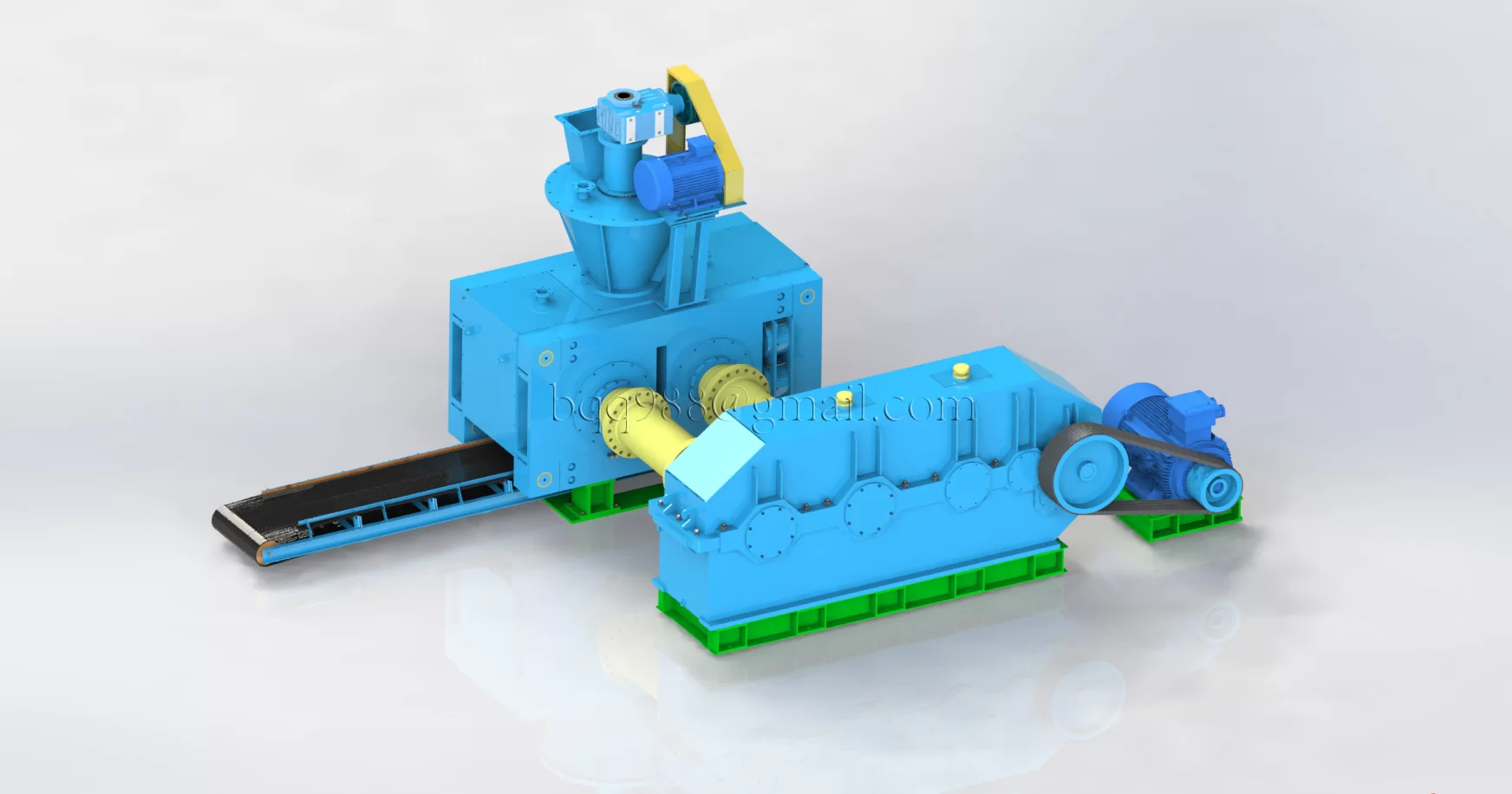

Types of briquetting machines

Foreword

As a key equipment in the powder material forming process, briquetting machines hold significant application value in fields such as mining and metallurgy, environmental protection, chemical engineering, and building materials. After decades of technological evolution, the industry has established a relatively standardized system of equipment models. However, in practical applications, due to differences in material characteristics (parameters including particle size distribution, moisture content, binding properties, etc.), the process parameter configuration, roller surface pocket design, and power system selection of briquetting machines all require targeted adjustments. This material-property-based customization demand results in significant technical variations among equipment of the same series during actual applications.

Types

The specific specifications of the equipment are as follows

Finally

The above technical parameters are only preliminary references for engineering selection. The actual equipment configuration must be based on the material compression characteristic curve. It is recommended to provide 2-5kg of representative material samples for laboratory briquetting test verification. Only after systematically optimizing the forming pressure, binder ratio, and moisture content parameters through experimental methods can a customized engineering design solution be determined.

For any related experimental requirements, please contact us.