Introduction to Stacker

Briquettes freshly produced by a briquetting machine typically possess limited inherent strength, withstanding only a few drops from low heights without breaking. However, constrained by space limitations at certain customer sites while requiring higher storage density within minimal footprints, designing a stacker crane becomes critical at this stage.

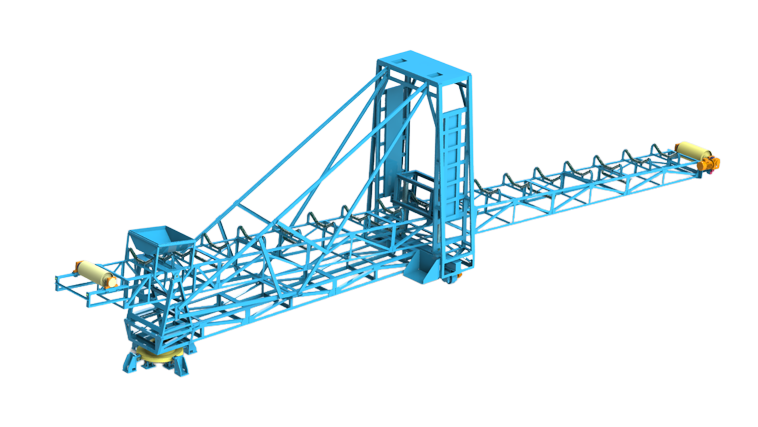

A stacker crane typically comprises components such as a conveyor, rotary assembly, lifting assembly, and mainframe. The rotary assembly actuates the conveyor to oscillate within a limited angle in the horizontal plane, while the lifting assembly drives the conveyor's vertical movement. This configuration forms a semi-circular material distribution zone, optimizing the utilization of constrained on-site space.

Key Advantages of Stacker Cranes:

1. During initial material distribution, positioning the conveyor at a low level effectively reduces briquette drop height, preventing fragmentation of compacted briquettes.

2. After the stockpile reaches a threshold height, elevating the conveyor's discharge end increases material storage capacity. Concurrently, the rotating function of the conveyor belt maximizes spatial utilization on site.