Features of the Small Briquetting Machine

In fact, the "Small Briquette Machine" is more aptly named a Laboratory Briquette Machine. This is because its primary function is testing the briquette formation characteristics of materials, such as the optimal binder ratio and briquette strength. The smallest model truly capable of continuous industrial production is the GY310 specification. If you're interested, you can refer to our previously published articles on the types of briquetting machines. However, for clarity throughout the following text, this laboratory briquette machine will still be referred to as the "Small Briquette Machine".

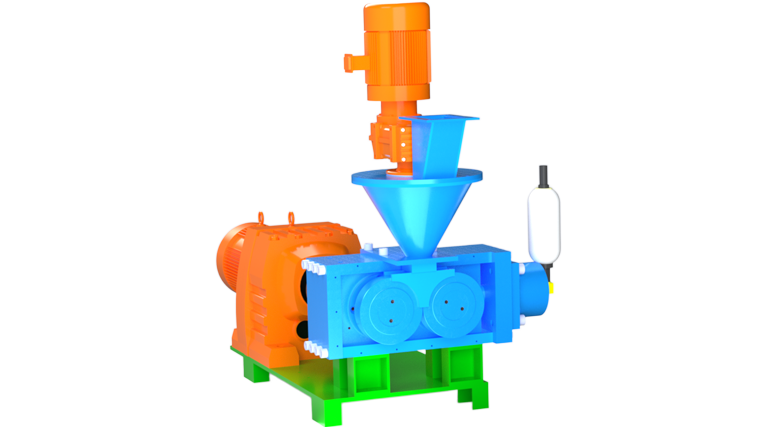

The primary characteristic of the Small Briquette Machine is its compact size. As previously mentioned, the equipment can be placed on a tabletop; in fact, a table measuring just 900mm × 900mm is sufficient to accommodate the entire setup. This makes equipment placement extremely simple within the typically very limited space of a laboratory.

The second characteristic of the Small Briquette Machine is its design simplicity. By eliminating redundant components and retaining only the essential ones, it significantly reduces the machine's weight while preserving its core functionality. For instance: the key feature of a high linear pressure ratio is maintained, equaling that of standard briquette machines, typically guaranteeing 8 tons per centimeter (8 t/cm). Furthermore, through optimization, this value can even exceed 10 tons per centimeter (10 t/cm).

The third characteristic of the Small Briquette Machine is its ease of maintenance and changeover. As the equipment needs to handle a wide variety of materials, and the required briquette shape differs for each material, this necessitates frequent changes of different roller sleeves. Through optimized design, the equipment ensures easy roller sleeve replacement while simultaneously guaranteeing efficient high-torque transmission during the briquetting process.

The fourth characteristic of the Small Briquette Machine is its high configuration flexibility. The hydraulic system can be optionally configured for manual or automatic operation; for the briquetting drive system, users can choose between standard inverter control or a servo system. This ensures that experimental testing can be conducted across the full speed range.