Our Featured Products

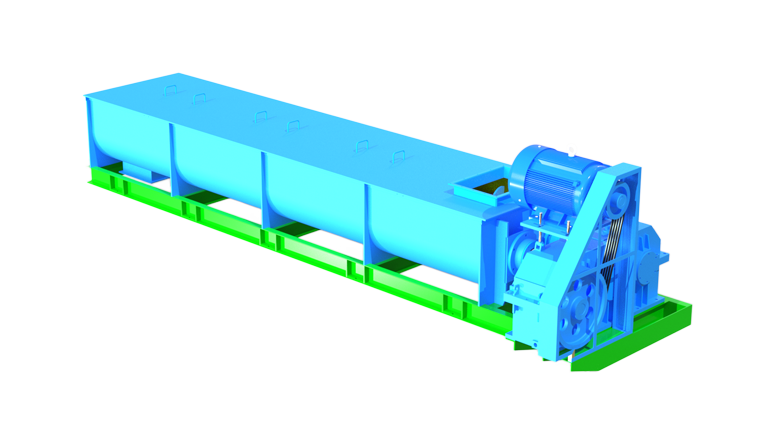

Double-shaft Mixer

The double-shaft mixer ensures thorough mixing of diverse materials, enhancing homogeneity and product quality in industrial processes.

Learn More

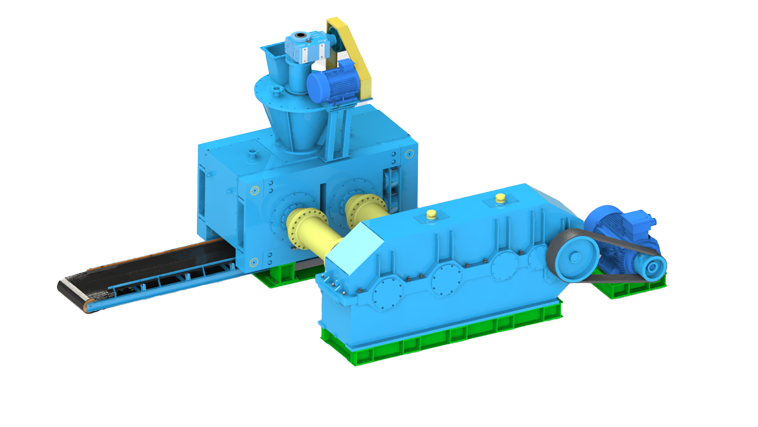

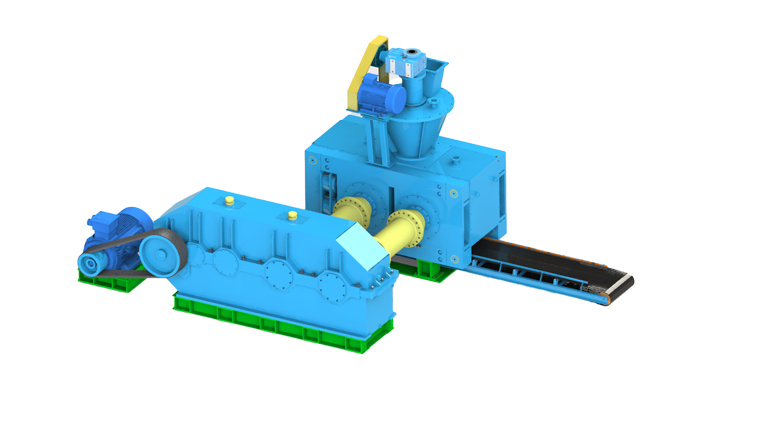

Briquetting Machine

Our briquetting machines compact powdered materials into high-density briquettes for efficient transportation and processing.

Learn More

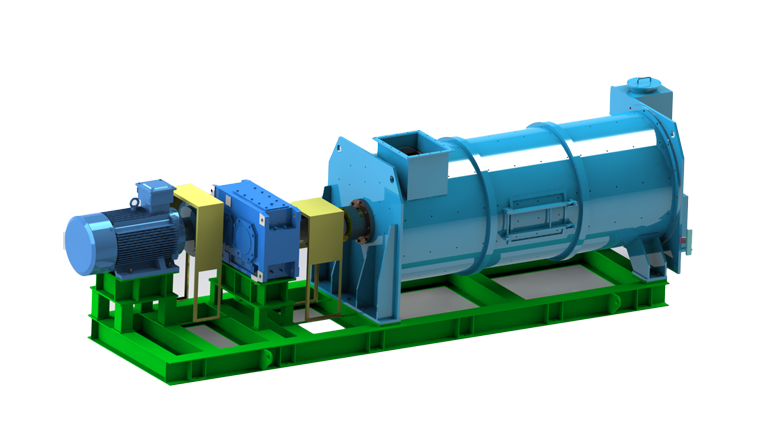

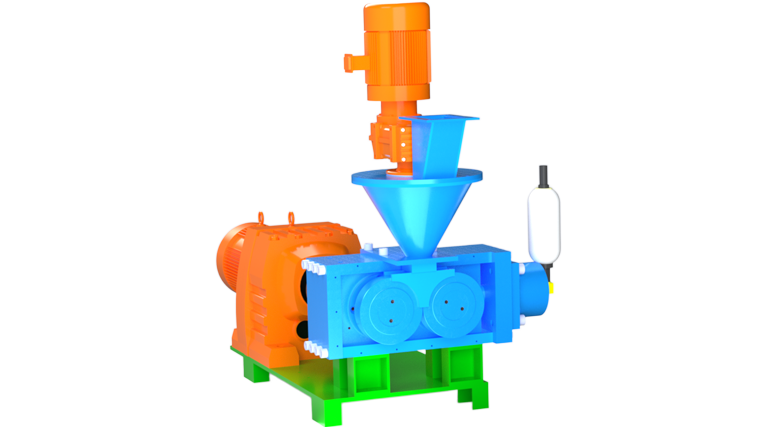

Horizontal Intensive Mixer

The horizontal intensive mixer delivers superior mixing performance for various industrial applications with consistent results.

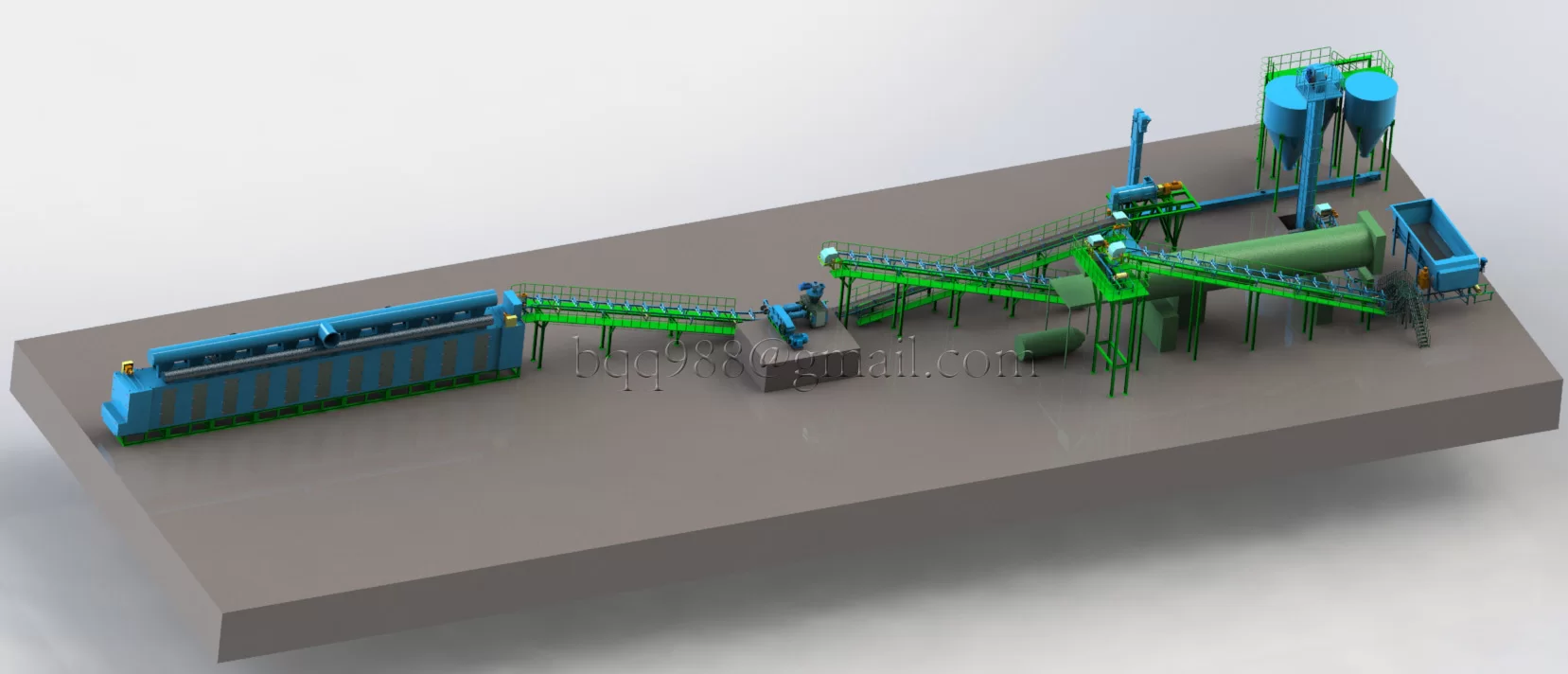

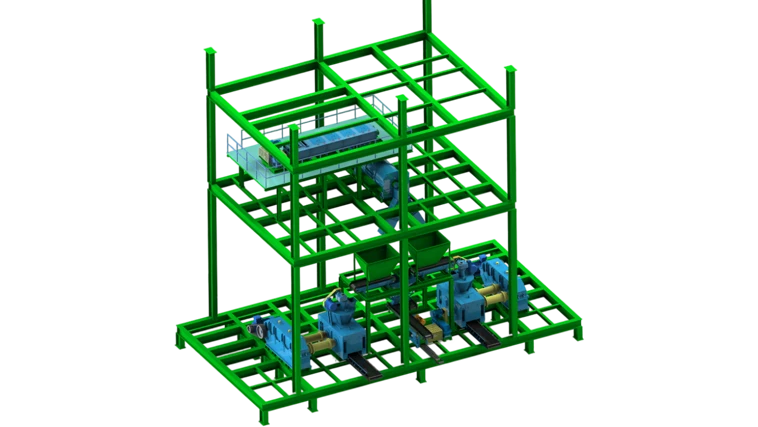

Learn MoreBriquetting Production Line

A complete briquetting production line consists of four integrated sections: raw material handling, precise batching, the briquetting process, and finished product quality control. This seamless integration ensures optimal performance and consistent output quality, with recycling mechanisms for any unqualified materials.

Latest News

Reasons Why Briquetting Fails

Discover the common causes behind briquetting machine failures and how to prevent them for optimal operation.

Read More

Meaning of Briquetting

Learn about the significance of briquetting technology in industrial applications and waste recycling processes.

Read More

Small Briquette Machine

Explore our compact briquetting solutions designed for testing and small-scale production requirements.

Read MoreReady to Enhance Your Production Line?

Contact our experts today to discuss your specific requirements and discover how our industrial equipment solutions can transform your operations.

Get In Touch